The following error codes are provided to help troubleshoot your system.

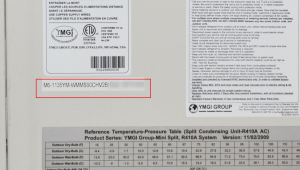

To determine which Error codes apply to your system, look at the serial number of your Outdoor Unit. Generally it can be found on the side or rear or the unit, where the refrigeration lines connect. On some units it will be located behind the wiring cover

In the event that you can’t find your serial number, your model number can also help figure out the correct error codes to use.

The prefix will tell you which M series Error Codes are correct for your unit

Example:

Serial #: M3-XXXXXX-WMMS-XXXXXXX(XX)-XXXXXXXXX

Use M3 Error Codes to diagnose

M6 Single & Multi Zone (56),(57),(58),(59)

| Protection/ Error Code | Description | Indoor Unit LED Display |

| C1 | Current arc protection | Running LED-Off 3S, Blinks 12 times |

| C2 | Current leakage protection | Running LED-Off 3S, Blinks 13 times |

| C3 | Mis-wiring protection | Running LED-Off 3S, Blinks 14 times |

| C5 | Jumper error protection | Running LED-Off 3S, Blinks 15 times |

| C6 | No-ground | Running LED-Off 3S, Blinks 16 times |

| Cd | Too much CO2 protection | TBD |

| CF | Current short-out protection | TBD (Buzzer will sound once every 2 sec.) |

| d1 | WSHP: UV light error | TBD |

| E0 | Commercial: Water pump overload/error/flow switch error | Running LED-Off 3S, Blinks 10 times |

| E1 | System high pressure protection | Running LED-Off 3S, Blinks 1 time |

| E2 | Anti-freezing protection (heat exchanger-ID, OD) | Running LED-Off 3S, Blinks 2 times |

| E3 | Low pressure protection (run cooling when OD is too cold) | Running LED-Off 3S, Blinks 3 times |

| E4 | Compressor dischage pressure too high | Running LED-Off 3S, Blinks 4 times |

| E5 | System/compressor current too high | Running LED-Off 3S, Blinks 5 times |

| E6 | Communication error (ID-OD) | Running LED-Off 3S, Blinks 6 times |

| E7 | Mode clash (some Indoor Units set to run cooling/fan, some set to run heating) | Running LED-Off 3S, Blinks 7 times |

| E9 | Indoor Unit Water Full Error | Cooling LED Flashing/Heating LED Flashing (both flashing) |

| EA | VRF: Oil valve protection | TBD |

| Ec | Commercial & VRF: Water flow protection (lack of water flow) | TBD |

| Ed | System temperature too high | TBD |

| EE | Memory chip error (U5) | Heating LCD-Off 3S, Blinks 15 times |

| EF | Outdoor fan motor overload | TBD |

| EL | Fire alarm | TBD |

| EP | Shell top high temperature protection | TBD |

| F0 | System refrigerant lack or restriction protection | Cooling LED-Off 3S, Blinks 10 times |

| F3 | Outdoor abmient temperature sensor error | Cooling LED-Off 3S, Blinks 3 times |

| F8 | Incoming water temperature sensor error | Cooling LED-Off 3S, Blinks 8 times |

| F9 | Outgoing water temperature sensor error | Cooling LED-Off 3S, Blinks 9 times |

| FA | Oil temperature sensor error | TBD |

| Fd | Suction gas temperature sensor error | TBD |

| FE | User side water sensor error | TBD |

| FL | Water tank-middle sensor error | TBD |

| FP | CO2 checking error | TBD |

| FU | Shell top temperature sensor error protection | TBD |

| H1 | Heating-Defrosting, or oil return | TBD |

| H2 | Static electric de-dust protection | Heating LED-Off 3S, Blinks 2 times |

| H3 | Compressor over-temperature protection | Heating LED-Off 3S, Blinks 3 times |

| H4 | System abnormal (many different other reasons…) | Heating LED-Off 3S, Blinks 4 times |

| H5 | IPM abnormal / Control Module Protection IPM Module protection, could be caused by over-charged refrigerant/high pressure (bad manifold gauge), restricted refrigerant flow or kinks on refrigerant pipes. Board failure due to age, insects, water exposure, power surge, lightning; or high current through the control board caused by any of these: failed fan motor, damaged fan blade, dirty coils outdoor and indoor units, airflow restricted by dirty filter, kinks in the copper lines, too much refrigerant, locked compressor, or other reasons. |

Heating LED-Off 3S, Blinks 5 times |

| H6 | Indoor fan motor-no feedback | Running LED-Off 3S, Blinks 11 times |

| H7 | Compressor loses steps, not being able to check rotor position | Heating LED-Off 3S, Blinks 7 times |

| HC | PFC board abnormal / PFC protection | Heating LED-Off 3S, Blinks 6 times |

| HE | Compressor de-managet protection (rotor locked /doesn’t rotate) | Heating LED-Off 3S, Blinks 14 times |

| L0 | Airflow switch error | TBD |

| L1 | Humidity sensor error | TBD |

| L2 | Water level switch error / hot water tank level switch error | TBD |

| L3 | Outdoor DC motor error (L3 for dual -mtor 1, LA for motor 2) | Running LED-Off 3S, Blinks 23 times |

| L4 | Filter clogged | TBD |

| L5 | Circulating water temperature sensor error | TBD |

| L6 | System capacity insufficient | TBD |

| L7 | Water pressure switch protection | TBD |

| Lc | Starting failure | Heating LED-Off 3S, Blinks 11 times |

| Ld | Power phase loss/lack | TBD |

| LE | Compressor locked | Running LED-Off 3S, Blinks 22 times |

| LF | Compressor over-speed protection | TBD |

| LH | Indoor ambient temperature too high | TBD |

| LL | Indoor ambient temperature too low | TBD |

| LP | Indoor-Outdoor units don’t match or power line connection error | Running LED-Off 3S, Blinks 19 times |

| P0 | Driving module resumed | TBD |

| P5 | Driving board checking-compressor current too high | Heating LED-Off 3S, Blinks 15 times |

| P6 | Driving board checking-communication error with indoor board | Heating LED-Off 3S, Blinks 16 times |

| P7 | Radiator loose, or IPM /PFC board sensor abnormal /error | Heating LED-Off 3S, Blinks 18 times |

| P8 | Radiator loose, or IPM /PFC board too hot | Heating LED-Off 3S, Blinks 19 times |

| P9 | AC contactor protection | TBD |

| PA | AC current protection (incoming) | TBD |

| Pc | Current checking-circuit error or current sensor error | TBD |

| Pd | Current checking-connection error (U-V-W not connected accordingly) | TBD |

| PE | Temperature sensor drifting protection | TBD |

| PF | Driving board-ambient temperature sensor error | TBD |

| PH | DC incoming voltage too high (program checking) | Cooling LED-Off 3S, Blinks 11 times |

| PL | DC incoming voltage too low (program checking) | Cooling LED-Off 3S, Blinks 21 times |

| PP | AC incoming power abnormal (too low or too high) | TBD |

| PU | Capacitor-charging circuit error | Heating LED-Off 3S, Blinks 17 times |

| U7 | 4-way switch valve abnormal | Heating LED-Off 3S, Blinks 20 times |

| U6 | Oil temperature too high | Heating LED-Off 3S, Blinks 16 times |

| U4 | Compressor rotation reversed | Heating LED-Off 3S, Blinks 14 times |

| U5 | Rectifying current checking error | Heating LED-Off 3S, Blinks 13 times |

| U3 | DC main bus voltage drop | Heating LED-Off 3S, Blinks 20 times |

| U1 | Compressor phase current checking circuit error | Heating LED-Off 3S, Blinks 13 times |

| U2 | Compressor phase loss protection | Heating LED-Off 3S, Blinks 12 times |

| UC | Filter needs to be cleaned | TBD |

| U8 | PG motor (indoor) checking circuit error | Running LED-Off 3S, Blinks 17 times |

| U9 | Outdoor fan motor checking circuit error | Running LED-Off 3S, Blinks 18 times |

| UF | De-actuate remote or control, from a long distance | TBD |

| C7 | PTC heater sensor error | Heating LED-Off 3S, Blinks 9 times |

| FJ | Discharge/vent air temperature sensor error | TBD |

| L8 | Storage tank water level switch error | TBD |

| d3 | AC condensate: anti-freezing sensor error | TBD |

| d4 | Domestic water: anti-freezing sensor error | TBD |

| d5 | Return water sensor error | TBD |

| d6 | Defrost coil sensor error | TBD |

| d7 | Back-up hot water temperature sensor error | TBD |

| d8 | Hot water outlet temperature sensor error | TBD |

| d9 | Hot water inlet temperature sensor error | TBD |

| db | Temp. Sensor Error-after metering device (cap. Tube, or EXV) | TBD |

| dc | Temp. Sensor Error-suction tube | TBD |

| dP | Temp. Sensor Error-discharge tube | TBD |

| dL | Low voltage reluctance/reluctor error | TBD |

| L9 | Compressor Protection-calculated input is too high | Running LED-Off 3S, Blinks 20 times |

| dF | Temp. Sensor Error-solar water heater-water outlet | TBD |

| dH | Temp. Sensor Error-solar water heater-assistant ele. heater | TBD |

| dU | Door-lock sensor: card is not in | TBD |

| dJ | AC phase protection (lost or reversed) | TBD |

| d0 | Fan motor speed communication error | TBD |

| Eo | Special function board error | TBD |

| dn | Mulitiple zone-pipe connection doesn’t match with comm. wire connection | TBD |

| Cn | Not for AC: Buring gas density too high | Cooling LED-Off 3S, Blinks 23 times |

| Fn | Not for AC: Buring gas sensor error | Running LED-Off 3S, Blinks 21 times |

| HP | Solar AC: solar power input voltage is higher than 180V | TBD |

| dA | AHU or RT: discharge air-relative humidity sensor error | TBD |

| dE | AHU or RT: fresh air-relative humidity sensor error | TBD |

| Fr | AHU or RT: fresh air-temp. sensor error | TBD |

| UA | DC inverter driving error 1 | TBD |

| dr | AHU or RT: air flow pressure sensor error | TBD |

| Ub | DC inverter driving error 2 | TBD |

| Ud | DC inverter driving error 3 | TBD |

| UE | DC inverter driving error 4 | TBD |

| LU | Compressor power input limit / decrease HZ (system power input) | Cooling LED-Off 3S, Blinks 24 times |

| LA | Outdoor unit fan motor protection (not rotating, or not connected). If 2 motors, motor 1-L3, motor 2-LA | Running LED-Off 3S, Blinks 24 times |

| A5 | Condensing coil-inlet temp. sensor error (=F5 in commercial units) | TBD |

| A7 | Condensing coil-outlet temp. sensor error (=F7 in commercial units) | TBD |

| e4 | Compressor dischage temp. (=pressure) too high | TBD |

| e8 | Over-load protection (outdoor coil temp. too high) | TBD |

| e1 | Dicharge pressure sensor error | TBD |

| ee | DC inverter driving chip error | TBD |

| JF | Indoor unit-testing board comm. Error (after 3-minutes) | TBD |

| rF | RF module error (once powered, the MCU tries to send commands, via SPI, to RF, if RF doesn’t receives it, error shows) | TBD |

| Uu | Solar AC: battery bank discharged too much and the output voltage is lower than 295V | TBD |

| no | For VRF groups: DC unit’s display board can not receive any data from the fixed speed comp. unit, will show “no” after 8 seconds | TBD |

| E6+IDU Temp. | Communication error (ID display-OD main board) and outdoor temperature sensor error | TBD |

| E7+ODU Temp. | Communication error (ID unit-OD unit) and outdoor temperature sensor error | TBD |

| Fu | AHU or RT: dust sensor error | TBD |

| e2 | Warning: water flow low | TBD |

| e3 | Oil level low protection | TBD |

| e7 | System pressure difference protection | TBD |

| eA | Heat exchanger-pressure transducer sensor error (similar to lower pressure transducer protection) | TBD |

| eC | Oil-pressure transducer sensor error (similar to lower pressure transducer protection) | TBD |

| e0 | Economizer-discharge temp. sensor error | TBD |

| e9 | Economizer-discharge pressure sensor error | TBD |

| eF | Compressor brand sensor error | TBD |

| bH | Water pump temp. sensor | TBD |

| oE | Any other error that the outdoor unit needs to stop | TBD |

| E8 | Anti-high temperature protection | Running LED-Off 3S, Blinks 8 times |

| E9 | Anti-cold blowing (discharging) protection | Running LED-Off 3S, Blinks 9 times |

| F1 | Indoor air temp. sensor error/bad-broken, shorted | Cooling LED-Off 3S, Blinks 1 time |

| F2 | Indoor coil temp. sensor error/bad-broken, shorted… | Cooling LED-Off 3S, Blinks 2 times |

| F4 | Outdoor coil temp. sensor error/bad-broken, shorted… | Cooling LED-Off 3S, Blinks 4 times |

| F5 | Compressor discharge temp. sensor error/bad-broken, shorted… | Cooling LED-Off 3S, Blinks 5 times |

| F7 | Cooling-oil return error | Cooling LED-Off 3S, Blinks 7 times |

| FC | Slide door error, or air louver mechanism error | TBD |

| FE | Over-load sensor error | TBD |

| H8 | Water level-high /overflow protection | Heating LED-Off 3S, Blinks 8 times |

| H9 | Ele. heater error | Heating LED-Off 3S, Blinks 9 times |

| b7 | Outlet temp. sensor error | Cooling LED-Off 3S, Blinks 22 times |

| b5 | Inlet temp. sensor error | Cooling LED-Off 3S, Blinks 19 times |

| d1 | DRM running mode 1 | |

| d2 | DRM running mode 2 | |

| d3 | DRM running mode 3 |

M8-(56)-G1-1198YM Single Zone (56) On-Grid Solar Heat Pump

M8-(56)-G1-1198YM Error Code list online

| E0 | Driving board communication error |

| E1 | Indoor unit air temperature sensor error |

| E3 | Indoor unit tube temperature sensor error |

| E6 | System refrigerant high pressure protection |

| E7 | System refrigerant low pressure protection |

| E8 | Indoor unit fan motor no feedback |

| F1 | Outdoor board IPM abnormal |

| F2 | Outdoor board inverter abnormal |

| F3 | Outdoor temperature sensor errors-discharge, tube, ambient air, etc. |

| F4 | Anti-freeze protection |

| F5 | Outdoor compressor discharge temperature too high |

| F6 | Outdoor compressor overload protection |

| F7 | Over current protection |

M8-(56)-G2-1201YM Single Zone (56) On-Grid Solar Heat Pump

| Code# | Code Descriptions | What to check |

| H1 | Protection-Refrigeration System High Pressure | Copper line vacuumed, leakage, refrigerant charge, fan motors working properly, filters/coils are clean |

| H2 | Protection-Refrigeration System Low Pressure | Copper line leakage, refrigerant charge, ambient temperatures |

| E1 | AC Voltage too high or too low | AC voltage ranges |

| E2 | DC Voltage too high | AC voltage ranges |

| E3 | DC Voltage too low | DC voltage ranges |

| E4 | Protection-AC input current too high |

AC current ranges, surge protector |

| E5 | Protection-Compressor current too high |

Compressor-resistances between any 2 leads (less than 1 Ohm), and any 1 lead against ground (must be OL), refrigerant charge too much, fan motor failure |

| E6 | System Pressure too high | Check refrigerant levels |

| E7 | Compressor-Phase loss | Compressor-lead wire connections matched diagrams, correct circuit breaker/wire connections |

| E8 | Protection-IPM not working properly | IPM board components |

| E9 | Starting failure | AC input, DC input, compressor, control boards, etc. |

| F0 | Driving board-communication error | Control board |

| F1 | Indoor unit temperature sensor error | Temperature sensor connection and resistance |

| F2 | Outdoor unit ambient temperature sensor error | Temperature sensor connection/contact and resistance |

| F3 | Indoor unit coil sensor error | Temperature sensor connection/contact and resistance |

| F4 | Outdoor unit defrost sensor error | Temperature sensor connection/contact and resistance |

| F5 | Compressor discharge temperature sensor error | Temperature sensor connection/contact and resistance |

| F6 | Protection-Indoor unit coil anti-freeze | Filter/coil clean, fan motor working, refrigerant charge |

| F7 | Protection-compressor discharge tube high temperature | Copper line vacuumed properly, filter/coil clean, temperature sensor connection/contact and resistance |

| F8 | Outdoor fan motor speed is not satisfied | Fan blade clogged, motor resistance, control board |

| F9 | Protection-Refrigerant leaking | Refrigerant leaking, all connections especially flare/nuts |

| FA | Protection-indoor fan motor no feedback | Fan motor wire connection/resistances, control board |

| FC | Outdoor unit fan motor error | Fan motor wire connection/resistances, control board |

Protection and Error Codes

| Code | Descriptions |

| C1 | AC Voltage higher than 254V, unit stops to work, error code stays on until AC voltage drops below 254V |

| C2 | AC Voltage lower than 197V, unit stops to work, error code stays on until AC voltage rises above 197V |

| C4 | DC Voltage higher than 350V, unit stops to work, error code stays on until DC voltage drops below 350V |

| C5 | DC Voltage lower than 150V, unit keeps on working, code stays on until DC voltage rises above 150V |

| C7 | Compressor over current/over load protection |

| C8 | Incorrect wiring between indoor unit and outdoor unit, unit stops to work until correction is made |

| P1 | Refrigerant pressure too HIGH, unit stops to work until error is cleared |

| P2 | Refrigerant pressure too LOW, unit stops to work until error is cleared |

| P6 | 4-way switching valve abnormal |

| A1 | Error of temperature sensor for indoor air temperatures-open, short or other issues |

| A2 | Error of temperature sensor for indoor coil tube temperatures-open, short or other issues |

| A3 | Error of temperature sensor for outdoor air temperatures-open, short or other issues |

| A4 | Error of temperature sensor for outdoor coil tube temperatures-open, short or other issues |

| A5 | Error of temperature sensor for outdoor compressor discharge temperatures-open, short or other issues |

| A6 | High temperature at compressor discharge tube, unit stops to work until error is cleared |

| A7 | High temperature at outdoor coil, unit stops to work until error is cleared |

| AC | Anti-freeze/anti-low temperature at indoor coil tube, unit keeps on working |

| F3 | No feedback at indoor fan motor |

| F6 | No feedback at outdoor fan motor |

| H1 | Compressor over load/over current protection |

| H7 | Compressor input power phase error |

| H8 | Driving board check compressor over current |

| b3 | Radiator or IPM, PFC module-Temperature sensor abnormal |

| b4 | Radiator or IPM, PFC module-Temperature too high |

| b5 | Compressor-loses steps, not detecting rotator position |

| b6 | PFC abnormal or protection |

| b7 | IPM abnormal or protection |

| b9 | Starting failure |

| bb | Communication error between driving board-main board |

| J3 | Storage chip error at driving board |

| J7 | Suction temperature sensor-open, short or other issues |

| J9 | Outdoor coil middle temperature sensor-open, short or other issues |

M8 Single Zone (86) All DC Solar Heat Pump

| ERROR CODE | DESCRIPTION | TROUBLE SHOOTING |

| E1 | Indoor Unit-Air Temperature Sensor error | Check resistances, contacts to the board |

| E2 | Indoor Unit-Tube Temperature Sensor error | Check resistances, contacts to the board |

| E3 | Indoor Unit-Fan Motor no feedback/error | Check motor, resistances, contacts to the board and filter |

| E4 | Outdoor Unit-voltage between + and – lower than 40VDC (12-24K 48V) or 20V (09K 24V) | Check charge controller, panel specs/connections |

| E5 | Outdoor Unit-voltage between + and – higher than 60VDC (12-24K 48V) or 30V (09K 24V) | Check charge controller, panel specs/connections |

| E6 | Outdoor Unit-refrigeration pressure too low | Check refrigerant pressure, and low pressure switch |

| E7 | Outdoor Unit-refrigeration pressure too high | Check fan motor, high pressure switch, and clean the filter |

| E8 | Outdoor Unit-refrigerant is low | Check refrigerant pressure, sensor, potential leak points before recharging |

| E9 | Indoor Unit-Protecting the coil from becoming frozen | Check refrigerant pressure, charge, sensor, potential leak points before recharge. Check Indoor fan motor, filter, and clean the coil. |

(78)1 SERIES 18.8-21.5 SEER Single Zone System

Error and Protection Codes

Indication on the outdoor unit

When the unit has an issue, or the compressor stops running, the LEDs on the outdoor control board will show the error sequence automatically.

Key: ★ : LIGHT ○ : FLASHING LIGHT X : OFF

| Outdoor Unit Failure Description |

LED 1 | LED 2 | LED 3 | Possible Cause |

| Lights will flash every second for the following faults | ||||

| Normal Operation | x | x | x | |

| Outdoor coil temperature sensor issue |

★ | X | ★ |

|

| Compressor exhaust temperature sensor issue | ★ | X | X |

|

| Communication failure between Indoor Unit and Outdoor Unit | X | X | ○ |

|

| Current Overload Protection |

★ | ○ | X |

|

| Maximum Current Protection |

★ | ○ | ★ |

|

| Communication issue between Outdoor Unit and Driver | X | ★ | ★ |

|

| Outdoor EEPROM issue |

★ | ★ | ★ |

|

| Compressor exhaust temperature is too high protection | X | ○ | ★ |

|

| Outdoor ambient temperature sensor issue | ★ | ★ | X |

|

| Compressor shell temperature too high protection | X | ★ | ○ |

|

| Anti-freeze protection with cooling or Overload protection with heating in Indoor Unit | X | ○ | ○ |

|

| Compressor drive issue |

○ | X | ○ |

|

| Locked rotor outdoor fan motor protection |

○ | ○ | ★ |

|

| Outdoor coil anti-overload protection with cooling | X | ★ | X |

|

| IPM module protection | X | ○ | X |

|

| PFC protection |

○ | X | X |

|

| Compressor preheating process |

○ | ★ | ○ |

|

| Outdoor board chip issue |

★ | X | ○ |

|

| AC voltage too high or too low protection |

★ | ★ | ○ |

|

| DC compressor |

○ | ○ | X |

|

| Outdoor ambient temperature too low protection | ★ | ○ | ○ |

|

| Light flash every 2 seconds for the following faults | ||||

| Outdoor radiator overheated protection | ○ | X | X |

|

| System high pressure failure protection |

○ | ○ | X |

|

When the compressor is in operation

Key: ★ : LIGHT ○ : FLASHING LIGHT X : OFF Flash cycle is 1 second

| No. | LED 1 | LED 2 | LED 3 | Reason current operating frequency of the compressor is limited |

| Lights will flash every second for the following faults | ||||

| 1 | ○ | ○ | ○ | Normal frequency increasing and decreasing. No limitation |

| 2 | x | x | ★ | Frequency decreasing or prohibition of frequency increasing caused by over current |

| 3 | x | ★ | ★ | Frequency decreasing or prohibition of frequency increasing caused by anti-freezing of refrigeration or anti-overload in heating |

| 4 | ★ | x | ★ | Frequency decreasing or prohibition of frequency increasing caused by compressor discharge temperature is too high |

| 5 | Limit to maximum operating frequency caused by low voltage | |||

| 6 | ★ | ★ | ★ | Operation at fixed frequency (in case of capability measuring or compulsory operation at fixed frequency) |

| 7 | ○ | x | x | Protective frequency decreasing against outdoor overload (over power, over frequency conversion rate, over torque, and detection of DC under-voltage) |

| 8 | ★ | x | x | Frequency decreasing caused by indoor and outdoor communication fault |

| 9 | x | ★ | ○ | Frequency decreasing or prohibition of frequency rising protection against overload of outdoor coiled pipe |

| 10 | x | ★ | x | Frequency decreasing or prohibition of frequency increasing for power-saving when it is being used simultaneously with other applications |

Indication on the Indoor Unit

The 88 display of the indoor display board will show the error code

automatically when the unit has the following issue

| Error Code | Error | Reason current operating frequency of the compressor is limited |

| EA | Error code indicates an issue with communication between the display board and control board |

|

If the unit has the following issue, and the compressor stops running, press the sleep button on the remote controller 10 times in 10 seconds, and the Indoor unit 88 display on the display board will show the error code. If two malfunctions happen at the same time, pressing the sleep button an additional 10 times in 10 seconds will display the second error code.

Note:

When you perform a troubleshooting inquiry using the Indoor unit 88 display, the error code will be displayed after entering the command with the remote control. If the error code can’t be displayed on the indoor unit, you will need to check the LED display board on the outdoor unit.

Key:★ : LIGHT ○ : FLASHING LIGHT X : OFF Flash cycle is 1 second

| Error Code | Running | Timer | Sleep | Power | Issue | Cause may be one of the following: |

| 1 | 2 | 3 | 4 | |||

| 0 | Normal Operation |

|||||

| 1 | X | ○ | X | X | Outdoor coil temperature sensor failure |

|

| 2 | X | ○ | ★ | X | Compressor exhaust temperature sensor issue |

|

| 5 | ★ | ○ | X | X | IPM module protection |

|

| 6 | ★ | ○ | X | ★ | AC voltage out of range protection |

|

| 7 | ★ | ○ | ★ | X | Communication failure between Indoor Unit and Outdoor Unit |

|

| 8 | ★ | ○ | ★ | ★ | Current overload protection |

|

| 9 | X | X | ○ | X | Maximum current protection |

|

| 10 | X | X | ○ | ★ | Communication issue between Outdoor unit and driver |

|

| 11 | X | ★ | ○ | X | Outdoor EEPROM issue |

|

| 12 | X | ★ | ○ | ★ | Outdoor ambient temperature too low |

|

| 13 | ★ | X | ○ | X | Compressor exhaust temperature too high protection |

|

| 14 | ★ | X | ○ | ★ | Outdoor ambient temperature sensor issue |

|

| 15 | ★ | ★ | ○ | X | Compressor shell temperature too high protection |

|

| 16 | Anti-freeze protection during cooling, or overload protection during heating |

|

||||

| 17 | PFC protection |

|

||||

| 18 | DC compressor start failure |

|

||||

| 19 | X | X | X | ○ | Compressor drive issue |

|

| 20 | ★ | X | X | ○ | Outdoor fan motor-locked rotor protection |

|

| 21 | Outdoor coil anti-overload protection while cooling |

|

||||

| 22 | Compressor preheating process |

|

||||

| 24 | Outdoor board chip issue |

|

||||

| 26 | Outdoor unit radiator overheated |

|

||||

| 27 | High system pressure protection |

|

||||

| 33 | ○ | X | X | ★ | Indoor unit temperature sensor failure |

|

| 34 | ○ | X | ★ | X | Indoor unit coil temperature sensor failure |

|

| 36 | ○ | ★ | X | ★ | Communication failure between Indoor unit and Outdoor unit |

|

| 38 | ○ | ★ | ★ | ★ | Indoor EEPROM failure |

|

| 39 | ○ | X | ★ | ★ | Indoor fan motor running abnormally |

|

| 41 | ★ | ★ | ○ | ★ | Indoor grounding protection failure |

|

LED Display

Key: ★ : LIGHT ○ : FLASHING LIGHT X : OFF Flash cycle is 1 second

| Error Code | Sleep | Timer | Running | Issue | Cause may be one of the following: |

| 1 | 2 | 3 | |||

| 0 | Normal Operation | ||||

| 1 | ○ | ★ | ★ | Outdoor coil temperature sensor failure |

|

| 2 | Compressor exhaust temperature sensor issue |

|

|||

| 5 | ★ | ○ | X | IPM module protection |

|

| 6 | X | ○ | X | AC voltage high or low protection |

|

| 7 | ★ | ★ | X | Communication failure between Indoor unit and Outdoor unit |

|

| 8 | Current overload protection |

|

|||

| 9 | Maximum current protection |

|

|||

| 10 | ★ | X | X | Communication issue between Outdoor unit and driver |

|

| 11 | ○ | X | X | Outdoor EEPROM issue |

|

| 12 | Low outdoor ambient temperature protection |

|

|||

| 13 | ○ | X | ★ | High compressor exhaust temperature protection |

|

| 14 | ★ | ★ | ○ | Outdoor ambient temperature sensor issue |

|

| 15 | X | ○ | ★ | High compressor shell temperature protection |

|

| 16 | ★ | X | ★ | Anti-freeze protection in cooling, or overload protection in heating |

|

| 17 | X | ★ | X | PFC protection |

|

| 18 | X | ★ | ★ | DC compressor start failure |

|

| 19 | X | ★ | ○ | Compressor drive issue |

|

| 20 | ★ | X | ○ | Outdoor fan motor locked rotor protection |

|

| 21 | X | X | ○ | Outdoor coil anti-overload protection while cooling |

|

| 22 | Compressor preheating protection |

|

|||

| 24 | Outdoor board chip issue |

|

|||

| 26 | Outdoor radiator overheated |

|

|||

| 27 | High system pressure protection |

|

|||

| 33 | ★ | ○ | ○ | Indoor temperature sensor failure |

|

| 36 | ○ | ★ | ○ | Communication failure between indoor and outdoor unit |

|

| 38 | ○ | ○ | X | Indoor EEPROM failure |

|

| 39 | ○ | ○ | ★ | Indoor fan motor running abnormally |

|

| 41 | X | X | ★ | Indoor ground protection failure |

|

A room temperature sensor failure is displayed if the sensor does not respond for over 5 seconds.

A heat exchange temperature sensor failure is displayed if the sensor does not respond for over 5 seconds.

A failure is displayed when the settings data does not match after the EEPROM self-checks two times.

A ground signal failure is displayed if the signal is not detected after the air conditioning system is powered ON.

M2 Single and Dual Zone 13/14 SEER Systems Error Codes

| Protection/ Error Codes | Description | Possible Reasons | Suggestion for User | Technician Trouble-Shooting |

| E1 | Condensate Full in drain pan |

|

|

|

| E2 | Indoor air temp. sensor failure |

|

|

|

| E3 | Indoor coil copper tube sensor failure |

|

||

| E4 | Abnormal cooling |

|

|

|

| E5 | Abnormal heating | |||

| E6 | Cooling-outdoor coil low temp. protection |

|

|

|

| E7 | Cooling-Indoor coil anti-freeze protection |

|

||

| E8 | Heating-outdoor coil high temperature protection |

|

||

| E9 | Heating-indoor coil anti-over heat protection |

|

||

| E0 | Heating-outdoor coil too cold protection |

|

M3 Single Zone 13 SEER Systems Error Codes

| Protection/ Error Code | Error Code – Light Signal | Error Indicated | Trouble Shooting |

| F4 | SLEEP & TIME light blink | Over-current protection | Check for abnomalities in the incoming power voltages, wire sizing/connections, system refrigerant charge level, vacuum level, restrictions etc. |

| F5 | WARM, SLEEP & TIME lights solid | EEPROM read error | Check wire connections. Shut off power, wait 30 seconds and restore power. |

| F6 | POWER, TIME light blink, SLEEP light solid | PG motor error | Check and debug the PG motor, its driving circuit, or feedback control circuit |

| F7 | POWER, SLEEP lights blink & TIME light solid | RT indoor air temperature sensor error | Chech sensor wire continuity, sensor resistance and installation |

| F8 | POWER, TIME & SLEEP light blink | PT indoor coil pipe temperature sensor error | Check sensor wire continuity, sensor resistance and installation |

| F9 | POWER & SLEEP light blink | OT outdoor coil pipe termperature sensor error | Check sensor wire continuity, sensor resistance and installation |

M1 16 SEER (57)2,3 Systems

Fault Code Display Table.

| Check parts | Serial number | Malfunction content | Indoor unit display status Code |

| Indoor parts | 1 | The communication faults in the indoor and outdoor units | F1 |

| 2 | Indoor ambient temp. sensor fault | F2 | |

| 3 | Indoor coil temperature sensor fault (Includes: Inlet, middle of pipe, outlet.) | F3 | |

| 4 | Indoor fan fault | F4 | |

| Outdoor parts | 1 | Outdoor module fault | F5 |

| 2 | Outdoor ambient temp. sensor fault | F6 | |

| 3 | Outdoor coil temp. sensor fault | F7 | |

| 4 | Compressor discharge temp. sensor fault |

F9 | |

| 5 | Compressor drive abnormal fault | FC | |

| 6 | Phase lacking or phase sequence fault |

FD | |

| 7 | Outdoor DC Motor | FH |

Note:

The above error code information is applicable to several models of air conditioners, but because of product changes or improvements, they can change. Please refer to the User’s Manual for more information, or have a technician contact YMGI.

Protection Display Table.

| Check parts | Serial number | Protection content | Indoor unit display status Code |

| Indoor parts | 1 | Evaporator temp protection | P1 |

| Outdoor parts | 1 | Overheat, over current protection of inverter module | P2 |

| 2 | Over current protection | P3 | |

| 3 | Compressor discharging temp. protection | P4 | |

| 4 | Overheat of compressor top protection | P5 | |

| 6 | Power supply over current/over voltage protection | P7 | |

| 9 | High temp of condenser protection | PA | |

| 10 | High temp of outdoor ambient protection | PC |

M1 Single Zone 13 SEER Systems

| Protection/ Error Code | Self-Check code of Running Lamp | Error Indicated |

| “dF” or Heating Icon blinks | Blinks 1 time/sec | Defrost Indication |

| Fan Motor Icon not Lit | Blinks 1 time/ sec | Anti-cold Wind |

| E2 | Blinks 1 time/ 8 sec | Room Temperature Sensor fault |

| E3 | Blinks 2 times / 8 sec | Coil Temperature Sensor |

| E8 | Blinks 3 times / 8 sec | Overheat Protection/Defrosting |

| E5 | Blinks 6 times / 8 sec | Indoor Fan Fault |

| E7 | Blinks 7 times / 8 sec | External Feedback Fault |

| E0 | Blinks 3 times / 8 sec | Open Door Fault |

| E1 | Blinks 4 times / 8 sec | Outdoor Tube Temperature Sensor Fault |

| E6 | Blinks 6 times / 8 sec | (EEPROM) Communication Failure(s) |

| FF | Blinks 1 time / sec | Outdoor Temperature Exceeds Operating Limits of System. |

M1 48 Series Systems

| LED | Running Lamp (blink no. times) |

Error | The reason of fault and solution |

| F1 | 1 | communication fault |

|

| F2 | 2 | ambient temp. sensor fault |

|

| F3 | 3 | coil pipe temp. sensor of indoor unit fault(inlet,middle,outlet) |

|

| F4 | 4 | fan motor of indoor |

|

| F5 | 5 | module of outdoor unit fault |

|

| F6 | 6 | ambient temp. sensor of outdoor fault |

|

| F7 | 7 | coil pipe temp. sensor of outdoor unit fault |

|

| F8 | 8 | suction temp. sensor of compressor fault |

|

| F9 | 9 | discharge temp. sensor of compressor fault |

|

| FA | 10 | inductor of current or voltage fault |

|

| FC | 11 | compressor drive fault |

|

| FD | 12 | phase lacking or phase sequence fault |

|

| FE | 13 | gas return sensor fault (include A,B,C,D) |

|

| FF | 14 | other fault | |

| P1 | 1 | temp. of evaporator protection |

|

| P2 | 2 | overheat, over current protection of inverter module |

|

| P3 | 3 | over current protection |

|

| P4 | 4 | discharge temp. of compressor |

|

| P5 | 5 | over heat of compressor top protection |

|

| P6 | 6 | suction temp. of compressor protection |

|

| P7 | 7 | low or high voltage protection |

|

| P8 | 8 | low presser of gas return protection |

|

| P9 | 9 | high pressure of discharge protection |

|

| PA | 10 | high temp. of condenser protection |

|

| PC | 11 | high temp. of outdoor ambient protection |

|

| PF | 12 | other protection |

M1 46 Series Systems

| LED | failure | The reason of fault and solution |

| F1 | communication fault |

|

| F2 | indoor temp. sensor fault |

|

| F3 | outlet e temp. sensor of indoor unit coil pipe fault |

|

| F3 | suction temp. sensor of indoor unit coil pipe fault |

|

| F3 | middle temp. sensor of indoor unit coil pipe fault |

|

| F4 | PG motor fault |

|

| P2 | protection of module fault |

|

| P3 | over current of outdoor unit |

|

| P4 | discharge temp. of compressor too high, outside ambient temp. too high, temp. switch of compressor crust cut off, temp. of module too high. |

|

| P7 | DC voltage abnormal of outdoor unit |

|

| P8 | lack refrigerant or reverse valve fault |

|

| F6 | outside sensor fault |

|

| FC | outdoor unit drive fault, start compressor failure |

|

PTAC Systems

| Malfunction | Possible Causes |

| Indoor ambient temperature sensor is open/short circuited |

|

| Indoor evaporator temperature sensor is open/short circuited |

|

| Outdoor ambient temperature sensor is open/short circuited |

|

| Low temperature prevention protection |

|

PTAC Series 0 Error Codes

Protective Auto Diagnostics

| Failure code | Content of defect |

| E2 | Indoor temperature sensor failure |

| E3 | Indoor coil temperature sensor failure |

| E4 | High temperature protection of air outlet |

| E5 | Outdoor coil temperature sensor failure |

| E8 | Overheating protection/defrosting |

| E9 | High temperature protection of outdoor coil |

TABLE OF ERROR CODES FOR OUTDOOR UNIT

| Error Code | Content |

| E0 | Outdoor Unit Error |

| E1 | High Pressure Protection |

| E2 | Discharge Low Temperature Protection |

| E3 | Low Pressure Protection |

| E4 | Excess Discharge Temperature Protection of Compressor |

| Ed | Low Refrigerant Protection |

| EN | Copressor Power Protection |

| F0 | Bad Performance of the Outdoor Mainboard |

| F1 | High Pressure Sensor Error |

| F3 | Low Pressure Sensor Error |

| F5 | Compressor 1 Discharge Temperature Sensor |

| F6 | Compressor 2 Discharge Temperature Sensor Error |

| F7 | Compressor 3 Discharge Temperature Sensor Error |

| F8 | Compressor 4 Discharge Temperature Sensor Error |

| F9 | Compressor 5 Discharge Temperature Sensor Error |

| FA | Compressor 6 Discharge Temperature Sensor Error |

| Fb | Compressor 2 Top Temperature Sensor Error |

| FC | Compressor 2 Current Sensor Error |

| Fd | Mode Exchanger Outlet Pipe Temperature Sensor Error |

| FE | Compressor 4 Current Sensor Error |

| FF | Compressor 5 Current Sensor Error |

| FH | Compressor 1 Current Sensor Error |

| FJ | Compressor 6 Current Sensor Error |

| FL | Compressor 3 Current Sensor Error |

| Fn | Mode Exchanger Inlet Pipe Temperature Sensor Error |

| FP | Malfunction of DC motor |

| FU | Compressor 2 Top Temperature Sensor Error |

| J1 | Compressor 1 Over-current Protection |

| J2 | Compressor 2 Over-current Protection |

| J3 | Compressor 3 Over-current Protection |

| J4 | Compressor 4 Over-current Protection |

| J5 | Compressor 5 Over-current Protection |

| J6 | Compressor 6 Over-current Protection |

| J7 | 4-way Valve Blow-by Protection |

| J8 | System Pressure Over-Ratio Protection |

| J9 | System Pressure Under-Ratio Protection |

| JA | Protection of Abnormal Pressure |

| JC | Protectionof Water Flow Switch |

| JE | Oil return pipe is blocked |

| JF | Oil return pipe is leaking |

| JL | Protection of Low High-pressure |

| b1 | Outdoor Ambient Temperature Sensor Error |

| b2 | Defrosting Temperature Sensor 1 Error |

| b3 | Defrosting Temperature Sensor 2 Error |

| b4 | Subcooler Liquid-out Temperature Sensor Error |

| b5 | Subcooler Gas-out Temperature Sensor Error |

| b6 | Gas-liquid separator inlet temperature sensor error |

| b7 | Gas-liquid separator outlet temperature sensor error |

| b8 | Outdoor Humidity Sensor Error |

| b9 | Heat Exchanger Gas-out Temperature Sensor Error |

| bA | Oil-return Temperature Sensor Error |

| bC | Compressor 1 Top Temperature Sensor Detachment Protection |

| bE | Malfunction of entry tube temperature sensor of condensor |

| bF | Malfunction of exit tube temperature sensor of condenser |

| bH | System Clock Malfunction |

| bJ | High and low pressure sensors are connected inversely |

| bL | Compressor 2 Top Temperature Sensor Detachment Protection |

| Fd | High pressure switch |

| P0 | Compressor Drive Board Error |

| P1 | Compressor Drive Board Malfunction |

| P2 | Protection of Compressor Drive Board Power Supply |

| P3 | Protection of Compressor Drive Board Module Reset |

| P4 | PFC Over current protection |

| Pn | PFC Module Overheat |

| PE | Phase loss protection of compressor |

| P5 | AC over current |

| P6 | IPM over current |

| P8 | IPM module overheat |

| P9 | Desynchronization protection |

| PH | Busbar over voltage protection |

| PC | Phase current detection fault |

| PL | Busbar under voltage protection |

| PF | Capacitor charge error |

| PU | Demagnitization protection |

| H0 | Error of Fan Drive Board |

| H1 | Malfunction of Fan Drive Board |

| H2 | Protection of Fan Drive Board Power Supply |

| – | — |

TABLE OF ERROR CODES FOR INDOOR UNIT

| Error Code | Content |

| E0 | Low Refrigerant Protection |

| E0 | Copressor Power Protection |

| EO | PFC Over current protection |

| EO | Middel Sensor Error |

| EO | High Pressure Switch |

| L0 | Indoor Unit Error |

| L1 | Indoor Fan Protection |

| L2 | E-heater Protection |

| L3 | Water Full Protection |

| L4 | Wired Controller Power Supply Error |

| L5 | Anti-Frosting Protection |

| L6 | Mode Conflict |

| L7 | No Master Indoor Unit Error |

| L8 | Power Insufficiency Protection |

| L9 | Quantity Of Group Control Indoor Units Setting Error |

| LA | Indoor Units Incompatibility Error |

| Lb | Inconsistency of Group-controlled Indoor Units in Reheat Dehumidification System |

| LC | Outdoor-Indoor Incompatibility Error |

| LF | Shunt Valve Setting Error |

| LH | Low Air Quanlity Warning |

| LJ | Wrong Setting ofFunction DIP Switch |

| LP | Zero-crossing malfunction of PG motor |

| LU | Inconsistent Branch of Group-controlled Indoor Units in Heat Recovery System |

| d1 | Indoor Unit PC-Board Error |

| d3 | Ambient Temperature Sensor Error |

| d4 | Inlet Pipe Temperature Sensor Error |

| d5 | Malfunction of middle tube temperature sensor |

| d6 | Outlet Pipe TemperatureSensor Error |

| d7 | Humidity Sensor Error |

| d8 | Water Temperature Abnormality |

| d9 | Jumper Cap Error |

| dA | Indoor Unit Hardware Address Error |

| db | Special Code:Field Debugging Code |

| dC | Capacity DIP Switch Setting Error |

| dE | Indoor Unit CO2 Sensor Error |

| dH | Wired Controller PC-Board Error |

| dL | Outlet Air Temperature Sensor Error |

| dn | Swing AssemblyError |

| P0 | PFC Module Overheat |

| P0 | Phase loss protection of compressor |

| P0 | AC over current |

| P0 | IPM over current |

| P0 | IPM module overheat |

| P0 | Desynchronization protection |

| P0 | Busbar over voltage protection |

| P0 | Phase current detection fault |

| P0 | Busbar under voltage protection |

| P0 | Capacitor charge error |

| P0 | Demagnitization protection |

| y7 | Fresh Air Inflow Temperature Sensor Error |

| y8 | Indoor Air Box Sensor Error |

| y9 | Outdoor AirBox Sensor Error |

| – | — |

TABLE OF DEBUGGING CODES

| Error Code | Content |

| U2 | Outdoor Unit Capacity Code/Jumper Cap Setting Error |

| U3 | Phase Sequence Protection of Power Supply |

| U4 | Protection of Lack of Refrigerant |

| U5 | Wrong Address of Compressor Drive Board |

| U6 | Valve Abnormal Alarm |

| U8 | Indoor Unit Tube Malfunction |

| U9 | Outdoor Unit Tube Malfunction |

| UC | Master indoor unit is successfully set |

| UE | Refrigerant Charging is ineffective |

| UF | Indoor Unit Identification Error of Mode Exchanger |

| UL | Emergency Operation DIP switch setting of the compressor is wrong |

| C0 | Communication between indoor unit and outdoor unit and the communication between indoor unit and wired controller have malfunction |

| C1 | 485 Communication Error between main controller and debugging controller |

| C2 | Communication error between master control and inverter compressor drive |

| C3 | Communication error between master control and inverter fan motor drive |

| C4 | Error of Lack of Indoor Unit |

| C5 | Alarm of Indoor Unit Project Number Collision |

| C6 | Alarm of Wrong Number of Outdoor Unit |

| C7 | Mode Exchanger Communication Error |

| Cb | Outflow of Units IPAddress |

| Cd | CommunicationFailure Between Mode Exchanger and Outdoor Unit |

| CE | Communication Failure Between Mode Exchanger and Indoor Unit |

| CF | Error of Multiple Master Indoor Unit |

| CH | Rated capacity is too high. |

| CJ | System addresses is incompatible. |

| CL | Rated capacity is too low. |

| Cn | Indoor and Outdoor NetworkError of Mode Exchanger |

| CP | Error of Multiple Master Wired Controller |

| CU | Communication Error between Indoor Unit and Remote Receiver |

| Cy | CommunicationError of No Master in Mode Exchanger |

TABLE OF STATUS CODES

| Error Code | Content |

| A0 | Unit is waiting for debugging |

| A1 | Check the compressor operation parameters |

| A2 | After-sales Refrigerant Reclaim |

| A3 | Defrosting |

| A4 | Oil return |

| A5 | Online Testing |

| A8 | Vacuum-pumping Mode |

| Ab | Emergency Stop |

| Ad | Operation Restriction |

| AC | Cooling |

| AF | Fan |

| AH | Heating |

| AJ | Filter Clean Reminder |

| AU | Remote Urgent Stop |

| n3 | Compulsory defrosting |

| qE | EVI Operating Mode |

SHCR Error Codes

| NO. | LED1 (GREEN) |

LED2 (RED) |

LED3 (RED) |

Status | Trouble Shooting |

| 1 | On | Off | Off | Cooling mode – normal operation | N/A |

| 2 | On | On | Off | Heating mode – normal operation | N/A |

| 3 | On | On | On | Defrosting mode – ongoing | N/A |

| 4 | On/On (AC/HP) |

Off/On (AC/HP) |

Blinks 3 times/ 5 seconds | Outdoor defrost temperature sensor failure | Check connectivity or resistance of this sensor, or replace with a new sensor. |

| 5 | On | Off | Blinks 1 times/ 5 seconds | Cooling Mode, High Pressure Protection is ON. The whole unit stops working until the problem is cleared, or power is turned off, and then restored, or another unit function is selected. |

Check possible causes: Mechanical or refrigerant blockage at the filter/drier. Too much refrigerant. 4-way valve is damaged. Faulty TEV or others. Electrical wiring connection is faulty. Component is damaged. Or switch Unit funtion. |

| 6 | On | Off | Blinks 2 times/ 5 seconds | Cooling Mode, Low Pressure Protection is ON. The whole unit stops working until the problem is cleared, or power is turned off, and then restored, or another unit function is selected. |

Check possible causes: Refrigerant is very low 4-way valve is damaged. Faulty TEV or others. Electrical wiring connection is faulty. Component is damaged. Or switch Unit funtion. |

| 7 | On | On | Blinks 1 times/ 5 seconds | Heating Mode, High Pressure Protection is ON. The whole unit stops working until the problem is cleared, or power is turned off, and then restored, or another unit function is selected. |

Check possible causes: Mechanical or refrigerant blockage at the filter/drier. Too much refrigerant. 4-way valve is damaged. Faulty TEV or others. Electrical wiring connection is faulty. Component is damaged. Or switch Unit funtion. |

| 8 | On | On | Blinks 2 times/ 5 seconds | Heating Mode, Low Pressure Protection is ON. The whole unit stops working until the problem is cleared, or power is turned off, and then restored, or another unit function is selected. |

Check possible causes: Refrigerant is very low 4-way valve is damaged. Faulty TEV or others. Electrical wiring connection is faulty. Component is damaged. Or switch Unit funtion. |

| No. | Error Code | Error |

| 1 | E1 | Compressor high pressure protection |

| 2 | E4 | Compressor air discharge high-temperature protection |

| 3 | E3 | Compressor low pressure protection, refrigerant lack protection and refrigerant collecting mode |

| 4 | F2 | Condenser temperature sensor error |

| 5 | F3 | Outdoor ambient temperature sensor error |

| 6 | F4 | Discharge temperature sensor error |

| 7 | F6 | ODU tube temperature sensor error |

| 8 | EE | ODU memory chip error |

| 9 | PF | Electric box sensor error |

| 10 | H3 | Compressor overload protection |

| 11 | H4 | Overload |

| 12 | H5 | IPM protection |

| 13 | H6 | DC fan error |

| 14 | H7 | Driver out-of-step protection |

| 15 | HC | Pfc protection |

| 16 | Lc | Startup failure |

| 17 | Ld | Compressor phase-sequence protection |

| 18 | LF | Power protection |

| 19 | U7 | 4–way valve switch-over error |

| 20 | P0 | Driver reset protection |

| 21 | P5 | Over-current protection |

| 22 | P6 | Master control and driver communication error |

| 23 | P7 | Driver module sensor error |

| 24 | P8 | Driver module high temperature protection |

| 25 | P9 | Zero-crossing protection |

| 26 | PA | AC current protection |

| 27 | Pc | Driver current error |

| 28 | Pd | Sensor connection protection |

| 29 | PE | Temperature drift protection |

| 30 | PL | Bus low-voltage protection |

| 31 | PH | Bus high-voltage protection |

| 32 | PU | Charge loop error |

| 33 | PP | Input voltage error |

| 34 | ee | Drive memory chip error |

| 35 | C4 | ODU jumper cap error |