Packaged Terminal Air Conditioner & Heat Pump (PTAC / PTHP)

PTAC/PTHPs are designed to cool and heat a room with a single piece of equipment. They are easy to install and efficient. There is no need for refrigeration piping or special wiring. A small section of the wall is cut out to install the wall sleeve, which houses the main unit. Units can be plugged into a standard electrical outlet or hard wired to a disconnect switch box.

High Efficiency

With SEER’s up to 12.6 and COP up to 3.6. All of our Harmony systems are AHRI Certified, and UL listed in the US and Canada.

Optimized System Design

Components are both individually and systematically optimized to ensure HARMONY systems work in wide ranges of applications, and deliver the right amount of heating or cooling when you need it, and with maximum efficiency.

How Do PTAC/PTHP Systems Work?

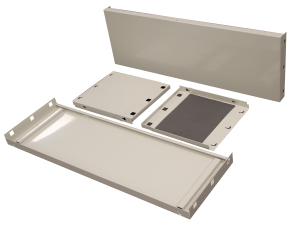

PTACs consist of 3 major components: the main unit, the wall sleeve, and the grille. PTAC systems utilize an electrically driven compressor to pump refrigerant through coils, pipes, and other components to cool indoor air and use an electric heater for warming the air.

PTHPs use an electrically driven compressor and can operate in a reverse cycle to heat a room. PTHPs also have an auxiliary electric heater that it can use when outdoor temperatures fall below freezing.

YMGI’s PTAC/PTHP systems are equipped with a locking air damper lever that allow control of the source air. Open the lever to let fresh air in. Close the lever to heat or cool more quickly and efficiently.

PTAC/PTHP Construction

PTAC/PTHP systems are larger than window mounted, or through-the-wall air conditioning systems. YMGI’s PTAC/PTHP systems mount through the wall. The main unit consists the evaporator coil, condensing coil, compressor and other components, all mounted to the powder coated steel chassis. YMGI offers a 42” x 16” x 13 3/4” powder coated steel knock-down wall sleeve that provides a sturdy housing for the refrigeration unit.

A PTAC/PTHP system’s larger condensing coil allows for greater cooling and heating capacities, higher energy efficiency, and noise levels as quiet as 47 dB.

YMGI offers stamped aluminum or architectural grille helps control air flow across, and protects the condensing coil. It attaches to the exterior side of the wall sleeve.

Quiet Operation

Unique low-noise design makes our systems some of the quietest on the market.

Back-up Electric Heater

YMGI offers PTAC systems equipped with electric heaters, so a single system can take care of all of a rooms heating or cooling needs. We also offer PTHP systems with a secondary electric heater that heats spaces in weather that may be too cold to effectively utilize a heat pump.

Perfect with Any Decor

The contemporary design and neutral color of these units make them ideal for any decor. The low profile fascia conceals the tactile controls and digital display.

The contemporary design and neutral color of these units make them ideal for any decor. The low profile fascia conceals the tactile controls and digital display.

YMGI’s PTAC/PTHP is equipped with a standard digital panel control. Systems come preconfigured for wired and wireless thermostats. YMGI PTAC/PTHP systems also come with Energy Managment & Thermostat connections and dip switches allowing you to use Door and Occupancy Sensors.

YMGI PTAC / PTHP provides precise temperature control so that guests can easily adjust the room to their comfort level.

Two efficient direct-drive motors lower noise and the 3-speed cross flow / random pitch indoor fan delivers consistent powerful heating and cooling throughout the room.

Units are available in cooling capacities from 7,000 to 16,200 Btu/h and heating capacities from 7,000 to 15,600 Btu/h with 3 or 5-KW back-up electric heat.

Available in two voltages: 208-230/1/60 and 265-277/1/60. LCDI cord comes with the unit.

Optional Accessories available: wall sleeve, grilles, drain kit and sub-base.

Perfect Temperature in Every Room

YMGI HARMONY PTAC/PTHP are fully self-contained systems, so each guests’ can experience personalized comfort. Room temperature is set using the tactile controls.

Easy Installation

The HARMONY STANDARD PTAC/PTHP systems use a rigid 4 piece knock-down wall sleeve to fit into a universal 42 ¼” x 16 ¼” opening. The grille is mounted to the sleeve on the exterior side, and secured from the inside. Condensate drains to the exterior. An easy to install optional condensate drain kit can be installed on heat pump models to allow drainage during winter. Finally, the system is plugged into a wall outlet or wired to a dedicated disconnect switch.

That’s it! Your HARMONY STANDARD system is now ready to cool and heat all your round.

Quality & More

Guests are tough on equipment, and YMGI’s HARMONY STANDARD systems are designed using thicker steel and fewer plastic parts than many competing systems on the market. Most of the steel components have a baked on powder coated finish, to ensure an attractive and rust free cabinet, and sleeve. The front panel is impact resistant ABS, molded in a neutral color, that easily coordinates with any rooms’ decor.

Comfort & Convenience

Air Filtration

Every YMGI indoor unit incorporates our washable and reusable particulate air filter. We also offer advanced filtration options, such as our active enzyme filter to eliminate bacteria, cold catalyst filter for removing pollen, dust, bacteria and harmful airborne chemicals from carpeting, flooring, paint and household cleaners, and our static electric filter for more thorough dust removal. With our selection of specialized filtration options, you can customize your indoor systems to your air quality needs.

Reduce Your Carbon Footprint

On average, over 30% of the heat generated by conventional central air systems escapes from the ducts before it ever reaches your rooms. The Symphony HARMONY systems let you reduce your carbon footprint by eliminating ducts, and eliminating energy waste.

Save Money

Every function of a HARMONY STANDARD system is aimed at reducing energy consumption and saving you money with lower energy costs while protecting the environment.

Eco-friendly Refrigerant

YMGI’s green mission doesn’t end with energy consumption. Older systems use R-22 refrigerant. Every YMGI system uses R-410A refrigerant, which is non-ozone depleting.

Condensate Evaporation

For rapid evaporation, the YMGI PTAC/PTHP uses a sling on the outdoor fan blades to throw condensate onto the outdoor coil. This increases cooling efficiency and minimizes water run-off.

Control All Your Systems from Your Computer

YMGI offers an optional control board and software package that will allow hotel operators to control all of their HARMONY PTAC systems in multiple buildings from single Windows PC. The software will display the full details of each system, and can be viewed from the front desk or remotely. The settings of each system can be monitored or controlled, and automatically generated emails can send remindersd when a system requires maintenance. Up to 170 PTAC/PTHPs can be monitored through a single controller. For buildings with over 170 systems, additional controllers can be installed to expand the network. This can also be used to monitor and control systems on multiple properties.

Trusted by the Biggest Names in Hospitality

YMGI’s PTAC and PTHP systems are used by some of the biggest names in the Hospitality Industry, in multiple locations across the United States.

Easily Replace Your Older Systems

YMGI HARMONY STANDARD systems fit into a standard 42 ¼” x 16 ¼” opening, to easily replace older less efficient or higher maintenance units.

With all these great features, discover the best value in state-of-the-art PTAC/PTHP systems.

| Models 208-230/1/60 | PTAC-07K-12B (43) | PTAC-09K-12B (43) | PTAC-12K-12B (43) | PTAC-15K-12B (43) | PTAC-15K-12B (45) | |

| Models 265-277/1/60 | PTAC-07K-12D(43) | PTAC-09K-12D(43) | PTAC-12K-12D(43) | PTAC-15K-12D(43) | PTAC-15K-12D(45) | |

| Cooling Capacity (Rated) | Btu/h | 7600/7700 | 8800/9000 | 11800/12000 | 14600/15000 | 14600/15000 |

| Heating Capacity (Rated) | Btu/h | – | – | – | – | – |

| Cooling Power Input | W | 620/640 | 770/800 | 1120/1120 | 1510/153 | 1510/1530 |

| Heating Power Input | W | – | – | – | – | – |

| Cooling Power Current | A | 3.0/2.8 | 3.9/3.7 | 5.3/5.1 | 7.6/6.7 | 7.5/6.7 |

| Heating Power Current | A | – | – | – | – | – |

| Rated Input (Without/With Ele. Heater) | W | 736/3000 | 893/3000 | 1394/3000 | 2025/3000 | 2025/5000 |

| Rated Current (Without/With Ele. Heater) | A | 3/14.4-13.0 | 4.78/14.4-3.0 | 7.57/14.4-13.0 | 11.03/14.4-13.0 | 11.03/24.0-21.7 |

| Rated Ele. Heater | KW | 3 | 3 | 3 | 3 | 5 |

| MCA | AMP | 17.0 | 17.3 | 18.6 | 19.5 | 28.5 |

| Recommended Circuit Breaker HVAC | AMP | 20 | 20 | 20 | 20 | 30 |

| Air Flow Rate (H/M/L) | CFM | 295/280/260 | 295/280/260 | 320/295/280 | 350/320/300 | 350/320/300 |

| Dehumidifying Volume | L/h | 0.8 | 1 | 1.3 | 1.5 | 1.5 |

| EER | Btu/h.w | 12.2/12 | 11.4/11.3 | 10.5/10.7 | 9.7/9.78 | 9.7/9.8 |

| COP | WW | – | – | – | – | – |

| Reference Only-Good for Floor Space, of Mild Load, in Residential Applications |

Sq. Ft | 100-160 | 120-180 | 160-240 | 210-310 | 210-310 |

| Climate Type | T1 | T1 | T1 | T1 | T1 | |

| Isolation | I | I | I | I | I | |

| Moisture Protection | IP24 | IP24 | IP24 | IP24 | IP24 | |

| Allowed Maximum Operation Pressure-High Side | PSI | 550 | 550 | 550 | 550 | 550 |

| Allowed Maximum Operation Pressure-Low Side | PSI | 290 | 290 | 290 | 290 | 290 |

| Dimensions of Main Unit WxHxD |

In. | 42×16.0x21.5 | 42×16.0x21.5 | 42×16.0x21.5 | 42×16.0x21.5 | 42×16.0x21.5 |

| Dimensions of Wall Sleeve WxHxD | In. | 42x16x13.75″ | 42x16x13.75″ | 42x16x13.75″ | 42x16x13.75″ | 42x16x13.75″ |

| Dimensions of Carton Box WxHxD | In. | 45.5×26.6×18.1 | 45.5×26.6×18.1 | 45.5×26.6×18.1 | 45.5×26.6×18.1 | 45.5×26.6×18.1 |

| Weight-Net | lbs. | 101.4 | 103.6 | 108.0 | 116.8 | 116.8 |

| Weight-Gross | lbs. | 125.7 | 127.9 | 132.3 | 141.1 | 141.1 |

| Refrigerant | R410A | R410A | R410A | R410A | R410A | |

| Charge | lbs. | 1.12 | 1.34 | 1.67 | 2.38 | 2.38 |

| Indoor Side | ||||||

| Fan Type | Cross-flow | Cross-flow | Cross-flow | Cross-flow | Cross-flow | |

| Fan Wheel Dia. x Length | In. | 4.8 x 27.8 | 4.8 x 27.8 | 4.8 x 27.8 | 4.8 x 27.8 | 4.8 x 27.8 |

| Fan Motor Speed(H/ML) | RPM | 840/790/740 | 1030/970/890 | 1100/1000/920 | 1100/1000/920 | 1100/1000/920 |

| Output of Fan Motor | W | 18 | 21 | 23 | 23 | 23 |

| Fan Motor RLA | A | 0.15 | 0.36 | 0.36 | 0.36 | 0.36 |

| Fan Motor Capacitor | UF | 1 | 1 | 1 | 1 | 1 |

| Input of Heater | W | 2452/3000 | 2452/3000 | 2452/3000 | 2452/3000 | 4087/5000 |

| Evaporator Form | Alumium Fin / Tube | Aluminum Fin-Copper Tube | Aluminum Fin-Copper Tube | Aluminum Fin-Copper Tube | Aluminum Fin-Copper Tube | |

| Pipe Diameter | In. | 5/16 | 5/16 | 9/32 | 9/32 | 9/32 |

| Row-FPI | 2-18 | 2-18 | 3-18 | 3-18 | 3-18 | |

| Coil Length (WxHxD) | In. | 27.5 x 9.53 x 1.5 | 27.5 x 9.53 x 1.5 | 27.5 x 9.53 x 1.5 | 27.5 x 9.53 x 1.5 | 27.5 x 9.53 x 1.5 |

| Fuse | A | 3.15 | 3.15 | 3.15 | 3.15 | 3.15 |

| Sound Pressure Level (H/M/L) | dB (A) | 49/48/47 | 51/50/49 | 53/52/51 | 53/52/51 | 53/52/51 |

| Sound Power Level (H/M/L) | dB (A) | 59/58/57 | 61/60/59 | 63/62/61 | 63/62/61 | 63/62/61 |

| Outdoor Side | ||||||

| Compressor Type | Rotary | Rotary | Rotary | Rotary | Rotary | |

| Compressor Brand | RECHI | MITSUBISHI | RECHI | RECHI | PANASONIC | |

| Compressor Model | 5RS062FAA21 | KN073NGFMC | 44A282AK&FEKC | 5PS146FAA21 | 5PS146FAA21 | |

| Compressor Oil | FV50S | PVE | NMOC Ze-Gles RB68EP | FV50S | FV50S | |

| Compressor RLA | A | 2.8 | 3.7 | 5 | 5 | 6.6 |

| Compressor Power Input | W | 630 | 740 | 1125 | 1125 | 1480 |

| Overload Protector | B130-140-241E | – | B245-140K-141H | B205-150-141C | B205-150-141C | |

| Metering Device | Capillary | Capillary | Capillary | Capillary | Capillary | |

| Panel Continued | F | 61°F-86°F | 61°F-86°F | 61°F-86°F | 61°F-86°F | 61°F-86°F |

| Outdoor Ambient Temp (Cooling) | °F | 55°-115° | 55°-115° | 55°-115° | 55°-115° | 55°-115° |

| Outdoor Ambient Temp (Heating) | °F | ≤75°F | ≤75°F | ≤75°F | ≤75°F | ≤75°F |

| Condenser | Aluminum Fin-Copper Tube | Aluminum Fin-Copper Tube | Aluminum Fin-Copper Tube | Aluminum Fin-Copper Tube | Aluminum Fin-Copper Tube | |

| Form Pipe Diameter | In. | 7/32 | 7/32 | 7/32 | 7/32 | 5/16 |

| Coil Length (WxHxD) | In. | 25 0 x 13.5 x 0.9 | 25 0 x 13.5 x 0.9 | 25 0 x 13.5 x 0.9 | 25 0 x 13.5 x 0.9 | 25 0 x 13.5 x 0.9 |

| Fan Motor Speed | RPM | 1370 | 1370 | 1370 | 1370 | 1370 |

| Output of Fan Motor | 40 | 40 | 65 | 65 | 65 | |

| Fan Motor RLA | A | 0.42 | 0.42 | 0.67 | 0.67 | 0.67 |

| Fan Motor Capacitor | UF | 2 | 2 | 2.5 | 2.5 | 2.5 |

| Air Flow Volume of Outdoor Side | CFM | – | – | – | – | – |

| Fan Type | Axial-flow | Axial-flow | Axial-flow | Axial-flow | Axial-flow | |

| Fan Diameter | In. | 13.75 | 13.75 | 13.75 | 13.75 | 13.75 |

| Sound Pressure Level (H/M/L) | dB (A) | 61/59/57 | 61/59/57 | 63/61/59 | 63/61/59 | 63/61/59 |

| Sound Power Level (H/M/L) | dB (A) | 71/69/67 | 71/69/67 | 73/71/59 | 73/71/59 | 73/71/59 |

| Defrosting Method | – | NA | NA | NA | NA | |

Optional Accessories Available:

Wall Sleeve,Grille, Drain Kit, Sub-Base, Wall Mount Thermostat,

Door Sensor, Occupancy Sensor.

| Models 208-230/1/60 | PTHP-07K-14B (43) | PTHP-09K-14B (43) | PTHP-12K-14B (43) | PTHP-15K-14B (43) | PTHP-15K-14B (45) | |

| Models 265-277/1/60 | PTHP-07K-14D(43) | PTHP-09K-14D(43) | PTHP-12K-14D(43) | PTHP-15K-14D(43) | PTHP-15K-14D(45) | |

| Cooling Capacity (Rated) | Btu/h | 7600/7700 | 8800/9000 | 11800/12000 | 14600/15000 | 14600/15000 |

| Heating Capacity (Rated) | Btu/h | 6100/6300 | 7900/8100 | 10500/10700 | 13800/13600 | 13800/13600 |

| Cooling Power Input | W | 620/640 | 770/800 | 1120/1120 | 1510/1530 | 1510/1530 |

| Heating Power Input | W | 530/540 | 700/720 | 990/1010 | 1390/1370 | 1390/1370 |

| Cooling Power Current | A | 3.0/2.8 | 3.9/3.7 | 5.3/5.1 | 7.5/6.7 | 7.5/6.7 |

| Heating Power Current | A | 3.0/208 | 3.6/3.4 | 4.7/4.5 | 6.0/6.6 | 6.0/6.6 |

| Rated Input (Without/With Ele. Heater) | W | 736/3000 | 972/3000 | 1447/3000 | 2025/3000 | 2025/5000 |

| Rated Current (Without/With Ele. Heater) | A | 3/14.4-13.0 | 5.36/14.4-13.0 | 7.87/14.4-13.0 | 11.03/14.4-13.0 | 11.03/24.0-21.7 |

| Rated Ele. Heater | KW | 3 | 3 | 3 | 3 | 5 |

| MCA | AMP | 17.0 | 17.3 | 18.6 | 19.5 | 28.5 |

| Recommended Circuit Breaker HVAC | AMP | 20 | 20 | 20 | 20 | 30 |

| Air Flow Rate (H/M/L) | CFM | 295/280/260 | 295/280/260 | 320/295/280 | 350/320/300 | 350/320/300 |

| Dehumidifying Volume | L/h | 0.8 | 1 | 1.3 | 1.5 | 1.5 |

| EER | Btu/h.w | 12.2/12 | 11.4/11.3 | 10.5/10.7 | 9.7/9.8 | 9.7/9.8 |

| COP | WW | 3.4/3.4 | 3.3/3.3 | 3.1/3.1 | 2.9/2.9 | 2.9/2.9 |

| Reference Only-Good for Floor Space, of Mild Load, in Residential Applications |

Sq. Ft | 100-160 | 120-180 | 160-240 | 210-310 | 210-310 |

| Climate Type | T1 | T1 | T1 | T1 | T1 | |

| Isolation | I | I | I | I | ||

| Moisture Protection | IP24 | IP24 | IP24 | IP24 | IP24 | |

| Allowed Maximum Operation Pressure-High Side | PSI | 550 | 550 | 550 | 550 | 550 |

| Allowed Maximum Operation Pressure-Low Side | PSI | 290 | 290 | 290 | 290 | 290 |

| Dimensions of Main Unit WxHxD |

In. | 42×16.0x21.5 | 42×16.0x21.5 | 42×16.0x21.5 | 42×16.0x21.5 | 42×16.0x21.5 |

| Dimensions of Wall Sleeve WxHxD | In. | 42x16x13.75″ | 42x16x13.75″ | 42x16x13.75″ | 42x16x13.75″ | 42x16x13.75″ |

| Dimensions of Carton Box WxHxD | In. | 45.5×26.6×18.1 | 45.5×26.6×18.1 | 45.5×26.6×18.1 | 45.5×26.6×18.1 | 45.5×26.6×18.1 |

| Weight-Net | lbs. | 101.4 | 105.8 | 110.2 | 119.0 | 119.0 |

| Weight-Gross | lbs. | 125.7 | 130.1 | 134.5 | 143.3 | 143.3 |

| Refrigerant | R410A | R410A | R410A | R410A | R410A | |

| Charge | lbs. | 1.23 | 1.56 | 1.67 | 2.38 | 2.38 |

| Indoor Side | ||||||

| Fan Type | Cross-flow | Cross-flow | Cross-flow | Cross-flow | Cross-flow | |

| Fan Wheel Dia. x Length | In. | 4.8 x 27.8 | 4.8 x 27.8 | 4.8 x 27.8 | 4.8 x 27.8 | 4.8 x 27.8 |

| Fan Motor Speed(H/ML) | RPM | 840/790/740 | 1030/970/890 | 1100/1000/920 | 1100/1000/920 | 1100/1000/920 |

| Output of Fan Motor | W | 21 | 21 | 23 | 23 | 23 |

| Fan Motor RLA | A | 0.36 | 0.36 | 0.36 | 0.36 | 0.36 |

| Fan Motor Capacitor | UF | 1 | 1 | 1 | 1 | 1 |

| Input of Heater | W | 2452/3000 | 2452/3000 | 2452/3000 | 2452/3000 | 4087/5000 |

| Evaporator Form | Alumium Fin / Tube | Aluminum Fin-Copper Tube | Aluminum Fin-Copper Tube | Aluminum Fin-Copper Tube | Aluminum Fin-Copper Tube | |

| Pipe Diameter | In. | 5/16 | 5/16 | 9/32 | 9/32 | 9/32 |

| Row-FPI | 2-18 | 2-18 | 3-18 | 3-18 | 3-18 | |

| Coil Length (WxHxD) | In. | 27.5 x 9.53 x 1.5 | 27.5 x 9.53 x 1.5 | 27.5 x 9.53 x 1.5 | 27.5 x 9.53 x 1.5 | 27.5 x 9.53 x 1.5 |

| Fuse | A | 3.15 | 3.15 | 3.15 | 3.15 | 3.15 |

| Sound Pressure Level (H/M/L) | dB (A) | 49/48/47 | 51/50/49 | 53/52/51 | 53/52/51 | 53/52/51 |

| Sound Power Level (H/M/L) | dB (A) | 59/58/57 | 61/60/59 | 63/62/61 | 63/62/61 | 63/62/61 |

| Outdoor Side | ||||||

| Compressor Type | Rotary | Rotary | Rotary | Rotary | Rotary | |

| Compressor Brand | PANASONIC | MITSUBISHI | RECHI | PANASONIC | PANASONIC | |

| Compressor Model | 5RS062FAA21 | KN073NGFMC | 44A282AK&FEKC | 5PS146FAA21 | 5PS146FAA21 | |

| Compressor Oil | FV50S | PVE | NMOC Ze-Gles RB68EP | FV50S | FV50S | |

| Compressor RLA | A | 2.8 | 3.7 | 5 | 5 | 6.6 |

| Compressor Power Input | W | 630 | 740 | 1125 | 1480 | 1480 |

| Overload Protector | B130-140-241E | – | B245-140K-141H | B205-150-141C | B205-150-141C | |

| Metering Device | Capillary | Capillary | Capillary | Capillary | Capillary | |

| Panel Continued | F | 61°F-86°F | 61°F-86°F | 61°F-86°F | 61°F-86°F | 61°F-86°F |

| Outdoor Ambient Temp (Cooling) | °F | 55°-115° | 55°-115° | 55°-115° | 55°-115° | 55°-115° |

| Outdoor Ambient Temp (Heating) | °F | ≤75°F | ≤75°F | ≤75°F | ≤75°F | ≤75°F |

| Condenser | Aluminum Fin-Copper Tube | Aluminum Fin-Copper Tube | Aluminum Fin-Copper Tube | Aluminum Fin-Copper Tube | Aluminum Fin-Copper Tube | |

| Form Pipe Diameter | In. | 7/32 | 7/32 | 7/32 | 7/32 | 5/16 |

| Coil Length (WxHxD) | In. | 25 0 x 13.5 x 0.9 | 25 0 x 13.5 x 0.9 | 25 0 x 13.5 x 0.9 | 25 0 x 13.5 x 0.9 | 25 0 x 13.5 x 0.9 |

| Fan Motor Speed | RPM | 1370 | 1370 | 1370 | 1370 | 1370 |

| Output of Fan Motor | 40 | 40 | 65 | 65 | 65 | |

| Fan Motor RLA | A | 0.42 | 0.42 | 0.67 | 0.67 | 0.67 |

| Fan Motor Capacitor | UF | 2 | 2 | 2.5 | 2.5 | 2.5 |

| Air Flow Volume of Outdoor Side | CFM | – | – | – | – | – |

| Fan Type | Axial-flow | Axial-flow | Axial-flow | Axial-flow | Axial-flow | |

| Fan Diameter | In. | 13.75 | 13.75 | 13.75 | 13.75 | 13.75 |

| Sound Pressure Level (H/M/L) | dB (A) | 61/59/57 | 61/59/57 | 63/61/59 | 63/61/59 | 63/61/59 |

| Sound Power Level (H/M/L) | dB (A) | 71/69/67 | 71/69/67 | 73/71/59 | 73/71/59 | 73/71/59 |

| Defrosting Method | NA | NA | NA | NA | NA | |

Optional Accessories Available:

Wall Sleeve,Grille, Drain Kit, Sub-Base, Wall Mount Thermostat,

Door Sensor, Occupancy Sensor.

PTAC w/ Electric Heater

| Model | PTAC-07K-04B(43) | PTAC-09K-04B(43) | PTAC-12K-04B(43) | PTAC-15K-04B(43) | PTAC-15K-04B(45) | ||

| Power supply | V/Ph/Hz | 208-230/1/60 | 208-230/1/60 | 208-230/1/60 | 208-230/1/60 | 208-230/1/60 | |

| Cooling (AC) | Capacity | Btu/h | 7400/7200 | 9500/9300 | 12200/12000 | 14500/14300 | 14500/14300 |

| Input | W | 620/605 | 835/815 | 1140/1120 | 1450/1430 | 1450/1430 | |

| EER | Btu/h.W | 11.9/11.9 | 11.4/11.4 | 10.7/10.7 | 10.0/10.0 | 10.0/10.0 | |

| Heating (Heat Pump) | Capacity | Btu/h | / | / | / | / | / |

| Input | W | / | / | / | / | / | |

| COP | Btu/h.W | / | / | / | / | / | |

| Electric heating | Capacity | Btu/h | 8300/10200 | 8300/10200 | 8300/10200 | 8300/10200 | 13900/17000 |

| Power input | W | 2450/3000 | 2450/3000 | 2450/3000 | 2450/3000 | 4085/5000 | |

| Rated current | A | 12/13.2 | 12/13.2 | 12/13.2 | 12/13.2 | 19.8/21.9 | |

| Cooling power factor | 0.992/0.994 | 0.987/0.990 | 0.956/0.963 | 0.985/0.991 | 0.985/0.991 | ||

| Heating power factor | / | / | / | / | / | ||

| Max. input consumption |

W | 750 | 1050 | 1460 | 1950 | 1950 | |

| Max. current | A | 3.6 | 5.1 | 7.3 | 9.4 | 9.4 | |

| Starting current | A | / | / | / | / | / | |

| Moisture Removal | Pints/hr | 0.21 | 1.16 | 2.18 | 3.27 | 3.27 | |

| Kg/hr | 0.12 | 0.66 | 1.24 | 1.86 | 1.86 | ||

| Compressor | Model | 39B142G | 39B202A | ASM113N1UDZ | 44B342U | 44B342U | |

| Type | Rotary | Rotary | Rotary | Rotary | Rotary | ||

| Brand | RECHI | RECHI | GMCC | RECHI | RECHI | ||

| Supplier | Rechi | Rechi | GMCC | Rechi | Rechi | ||

| Capacity | Btu/h | 5555 ± 5 % | 7815 ± 5 % | 11500/11450 ± 5% | 13370 ± 5% | 1337 0± 5% | |

| Input | W | 565 ± 5 % | 790 ± 5 % | 1090/1075 ± 5% | 1330 ± 5% | 1330 ± 5% | |

| Rated current (RLA) | A | 2.5 | 3.5 | 4.9/5.3 ± 5% | 5.9 | 5.9 | |

| Locked rotor Amp (LRA) |

A | 13±10% | 16.5±10% | 28.5±10% | 28.9±10% | 28.9±10% | |

| Thermal protector |

°C; | 135±5 (Built-in) |

135±5 ((External) |

135±5 (Built-in) |

135±5 (Built-in) |

135±5 (Built-in) |

|

| Capacitor | uF | 15 | 25 | 40 | 30 | 30 | |

| Refrigerant oil |

ml | 240 | 240 | 320 | 370 | 370 | |

| Indoor fan motor | Model | YDK-25-4P2 | YDK-25-4P2 | YDK-30-4P2 | YDK-30-4P2 | YDK-30-4P2 | |

| Type | Single-axis

structure motor |

Single-axis structure motor |

Single-axis structure motor |

Single-axis

structure motor |

Single-axis

structure motor |

||

| Brand | KB/CG | KB/CG | KB/CG | KB/CG | KB/CG | ||

| Insulation class |

A | A | A | A | A | ||

| Safe class | IP20 | IP20 | IP20 | IP20 | IP20 | ||

| Input | W | 55 | 55 | 64 | 64 | 64 | |

| Output | W | 25 | 25 | 30 | 30 | 30 | |

| Rated current |

A | 0.25 | 0.25 | 0.29 | 0.29 | 0.29 | |

| Capacitor | uF | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Speed (hi/mi/lo) |

rpm | 900/650 | 900/650 | 1050/850 | 1050/950 | 1050/950 | |

| Indoor fan wheel | Material | Aluminum Alloy |

Aluminum Alloy |

Aluminum Alloy |

Aluminum Alloy |

Aluminum Alloy |

|

| Type | Cross-flow fan blade |

Cross-flow fan blade |

Cross-flow fan blade |

Cross-flow fan blade |

Cross-flow fan blade |

||

| Diameter | mm | 120mm | 120mm | 120mm | 120mm | 120mm | |

| Inch | 4.724″ | 4.724″ | 4.724″ | 4.724″ | 4.724″ | ||

| Height | mm | 706mm | 706mm | 706mm | 706mm | 706mm | |

| Inch | 27.795″ | 27.795″ | 27.795″ | 27.795″ | 27.795″ | ||

| Indoor coil | Number of rows |

2 | 2 | 2 | 3 | 3 | |

| Tube pitch(a) x row pitch(b) |

mm | 21 x 13.37 | 21 x 13.37 | 21 x 13.37 | 21 x 13.37 | 21 x 13.37 | |

| Fin spacing | mm | 1.4 | 1.4 | 1.4 | 1.6 | 1.6 | |

| Fin type (code) |

Window fin | Window fin | Window fin | Window fin | Window fin | ||

| Tube outside dia. and type |

mm | φ7×0.24+0.18×C | φ7×0.24+0.18×C | φ7×0.24+0.18×C | φ7×0.24+0.18×C | φ7×0.24+0.18×C | |

| Screwed pipe |

Screwed pipe |

Screwed pipe |

Screwed pipe |

Screwed pipe |

|||

| Coil length x height |

mm | 704*252 | 704*252 | 704*252 | 722*252 | 722*252 | |

| Number of circuits |

2 | 2 | 2 | 2 | 2 | ||

| Indoor air flow (Hi/Lo) |

m3/h | 720/620 M3/h |

720/620 M3/h |

750/650 M3/h |

800/700 M3/h |

800/700 M3/h |

|

| Indoor air flow (Hi/Lo) |

CFM | 424/365 CFM | 424/365 CFM | 442/383 CFM | 471/412 CFM | 471/412 CFM | |

| Indoor external static pressure (Hi) |

Pa | 0 | 0 | 0 | 0 | 0 | |

| Indoor sound level (sound pressure level) |

dB(A) | 49/41 | 49/40 | 53/47 | 52/49 | 52/49 | |

| Outdoor fan motor | Model | YDK-55-4P2-4 | YDK-55-4P2-4 | YDK-55-4P2-4 | YDK-55-4P2-4 | YDK-55-4P2-4 | |

| Type | Uniaxial iron shell |

Uniaxial iron shell |

Uniaxial iron shell |

Uniaxial iron shell |

Uniaxial iron shell |

||

| Brand | GI | GI | GI | GI | GI | ||

| Insulation class |

A | A | A | A | A | ||

| Safe class | IPX4 | IPX4 | IPX4 | IPX4 | IPX4 | ||

| Input | W | 104 | 104 | 104 | 104 | 104 | |

| Output | W | 55 | 55 | 55 | 55 | 55 | |

| Rated current |

A | 0.46 | 0.46 | 0.46 | 0.46 | 0.46 | |

| Capacitor | uF | 3 | 3 | 3 | 3 | 3 | |

| Speed | rpm | 1600 | 1600 | 1600 | 1600 | 1600 | |

| Outdoor fan | Material | ABS+G15 | ABS+G15 | ABS+G15 | ABS+G15 | ABS+G15 | |

| Type | Axial-flow | Axial-flow | Axial-flow | Axial-flow | Axial-flow | ||

| Diameter | mm | 348 | 348 | 348 | 348 | 348 | |

| Height | mm | 104 | 104 | 104 | 104 | 104 | |

| Outdoor coil | Number of rows |

2 | 2 | 2 | 3 | 3 | |

| Tube pitch(a)x row pitch(b) |

mm | 14.5*12.56 | 14.5*12.56 | 14.5*12.56 | 21*13.37 | 21*13.37 | |

| Fin spacing | mm | 1.3 | 1.3 | 1.3 | 1.5 | 1.5 | |

| Fin type (code) |

Hydrophilic Window fin |

Hydrophilic

Window fin |

Hydrophilic

Window fin |

Hydrophilic

Window fin |

Hydrophilic

Window fin |

||

| Tube outside coil |

Dia.-mm | φ5 | φ5 | φ5 | φ7 | φ7 | |

| Type | φ4.9×0.2+0.15×C | φ4.9×0.2+0.15×C | φ4.9×0.2+0.15×C | φ7×0.24+0.18×C | φ7×0.24+0.18×C | ||

| Coil length x height |

mm | 676×348 | 676×348 | 676×348 | 676×336 | 676×336 | |

| Number of circuits |

4 | 2 | 2 | 4 | 4 | ||

| Outdoor air flow | m3/h | 1200 | 1200 | 1200 | 1200 | 1200 | |

| CFM | 706.8 | 706.8 | 706.8 | 706.8 | 706.8 | ||

| Outdoor sound level (sound pressure level) |

dB(A) | 66 | 66 | 66 | 66 | 66 | |

| Unit | Dimension (WxHxD) |

mm | 1066 x 408 x 535 mm | 1066 x 408 x 535 mm | 1066 x 408 x 535 mm | 1066 x 408 x 535 mm | 1066 x 408 x 535 mm |

| Inch | 41.97 x 16.06 x 21.06 in | 41.97 x 16.06 x 21.06 in | 41.97 x 16.06 x 21.06 in | 41.97 x 16.06 x 21.06 in | 41.97 x 16.06 x 21.06 in | ||

| Packing (W*H*D) |

mm | 1150 x 480 x 630 mm | 1150 x 480 x 630 mm | 1150 x 480 x 630 mm | 1150 x 480 x 630 mm | 1150 x 480 x 630 mm | |

| Inch | 45.28 x 18.9 x 24.8 inches | 45.28 x 18.9 x 24.8 inches | 45.28 x 18.9 x 24.8 inches | 45.28 x 18.9 x 24.8 inches | 45.28 x 18.9 x 24.8 inches | ||

| Net/Gross weight |

Kg | 42.5 / 47.5 Kg | 42.5 / 47.5 Kg | 46 / 51 Kg | 49 / 54 Kg | 49 / 54 Kg | |

| Lbs. | 93.6 / 104.6 LBs | 93.6 / 104.6 LBs | 101.3 / 112.3 LBs | 107.9 / 118.9 LBs | 107.9 / 118.9 LBs | ||

| Refrigerant Charge |

g | 570g | 550g | 750g | 970g | 970g | |

| Oz. | 20.11OZ | 19.4OZ | 26.46OZ | 34.22OZ | 34.22OZ | ||

| Metering Device | Capillary | Capillary | Capillary | Capillary | Capillary | ||

| Design pressure |

MPa | 3.1/1.6 MPa | 3.1/1.6 MPa | 3.1/1.6 MPa | 3.1/1.6 MPa | 3.1/1.6 MPa | |

| PSIG | 450/232 PSIG |

450/232 PSIG |

450/232 PSIG |

450/232 PSIG |

450/232 PSIG |

||

| Power Wires | Wire Size | mm2 | 3.3081 | 3.3081 | 3.3081 | 5.2615 | 5.2615 |

| LCDI Cord Plug |

Built-in | LCDI-20A | LCDI-20A | LCDI-20A | LCDI-20A | LCDI-30A | |

| Controller | Standard: Touch Pad Optional: Remote Remote Energy Management Ready |

Standard: Touch Pad Optional: Remote Remote Energy Management Ready |

Standard: Touch Pad Optional: Remote Remote Energy Management Ready |

Standard: Touch Pad Optional: Remote Remote Energy Management Ready |

Standard: Touch Pad Optional: Remote Remote Energy Management Ready |

||

| Indoor controllable temperature ranges |

°C | 16-32°C | 16-32°C | 16-32°C | 16-32°C | 16-32°C | |

| °F | 61-90°F | 61-90°F | 61-90°F | 61-90°F | 61-90°F | ||

| Outdoor ambient temperature ranges |

°C | Back-up Elec. Heater ≤ -8.3°C HP ≤ 5°C AC ≤46.1°C |

Back-up Elec. Heater ≤ -8.3°C HP ≤ 5°C AC ≤46.1°C |

Back-up Elec. Heater ≤ -8.3°C HP ≤ 5°C AC ≤46.1°C |

Back-up Elec. Heater ≤ -8.3°C HP ≤ 5°C AC ≤46.1°C |

Back-up Elec. Heater ≤ -8.3°C HP ≤ 5°C AC ≤46.1°C |

|

| °F | Back-up Elec. Heater ≤ 17°F HP ≤ 41°F AC ≤ 115°F |

Back-up Elec. Heater ≤ 17°F HP ≤ 41°F AC ≤115°F |

Back-up Elec. Heater ≤17°F HP ≤ 41°F AC ≤115°F |

Back-up Elec. Heater ≤17°F HP ≤ 41°F AC ≤115°F |

Back-up Elec. Heater ≤ 17°F HP ≤ 41°F AC ≤ 115°F |

||

PTHP Specifications

| Model | PTHP-07K-04B(43) | PTHP-09K-04B(43) | PTHP-12K-04B(43) | PTHP-15K-04B(43) | PTHP-15K-04B(45) | ||

| Power supply | V/Ph/Hz | 208-230/1/60 | 208-230/1/60 | 208-230/1/60 | 208-230/1/60 | 208-230/1/60 | |

| Cooling (AC) | Capacity | Btu/h | 7200/6800 | 9200/9000 | 12000/11800 | 14500/14300 | 14500/14300 |

| Input | W | 605/570 | 805/790 | 1130/1110 | 1450/1430 | 1450/1430 | |

| EER | Btu/h.W | 11.9/11.9 | 11.4/11.4 | 10.6/10.6 | 10.0/10.0 | 10.0/10.0 | |

| Heating (Heat Pump) | Capacity | Btu/h | 6000/5800 | 8300/8100 | 10800/10500 | 13600/13200 | 13600/13200 |

| Input | W | 520/500 | 715/700 | 960/930 | 1245/1210 | 1245/1210 | |

| COP | Btu/h.W | 3.4/3.4 | 3.4/3.4 | 3.3/3.3 | 3.2/3.2 | 3.2/3.2 | |

| Electric heating | Capacity | Btu/h | 8300/10200 | 8300/10200 | 8300/10200 | 8300/10200 | 13900/17000 |

| Power input | W | 2450/3000 | 2450/3000 | 2450/3000 | 2450/3000 | 4085/5000 | |

| Rated current | A | 12/13.2 | 12/13.2 | 12/13.2 | 12/13.2 | 19.8/21.9 | |

| Cooling power factor | 0.992/0.994 | 0.987/0.990 | 0.956/0.963 | 0.985/0.991 | 0.985/0.991 | ||

| Heating power factor | 0.990/0.991 | 0.987/0.988 | 0.936/0.940 | 0.983/0.991 | 0.983/0.991 | ||

| Max. input consumption | W | 750 | 1050 | 1460 | 1950 | 1950 | |

| Max. current | A | 3.6 | 5.1 | 7.3 | 9.4 | 9.4 | |

| Starting current | A | / | / | / | / | / | |

| Moisture Removal | Pints/hr | 0.21 | 1.16 | 2.18 | 3.27 | 3.27 | |

| Kg/hr | 0.12 | 0.66 | 1.24 | 1.86 | 1.86 | ||

| Compressor | Model | 39B142G | 39B202A | ASM113N1UDZ | 44B342U | 44B342U | |

| Type | Rotary | Rotary | Rotary | Rotary | Rotary | ||

| Brand | RECHI | RECHI | GMCC | RECHI | RECHI | ||

| Supplier | Rechi | Rechi | GMCC | Rechi | Rechi | ||

| Capacity | Btu/h | 5555± 5 % | 7815± 5 % | 11500/11450±5% | 13370±5% | 13370±5% | |

| Input | W | 565 ± 5 % | 790 ± 5 % | 1090/1075 ±5% | 1330 ±5% | 1330 ±5% | |

| Rated Current (RLA) | A | 2.5 | 3.5 | 4.9/5.3 ±5% | 5.9 | 5.9 | |

| Locked Rotor Amp (LRA) | A | 13±10% | 16.5±10% | 28.5±10% | 28.9±10% | 28.9±10% | |

| Thermal protector | °C; | 135±5 (Built-in) | 135±5 (External) | 135±5 (Built-in) | 135±5 (Built-in) | 135±5 (Built-in) | |

| Capacitor | uF | 15 | 25 | 40 | 30 | 30 | |

| Refrigerant oil | ml | 240 | 240 | 320 | 370 | 370 | |

| Indoor Fan Motor | Model | YDK-25-4P2 | YDK-25-4P2 | YDK-30-4P2 | YDK-30-4P2 | YDK-30-4P2 | |

| Type | Single-axis structure motor |

Single-axis structure motor |

Single-axis structure motor |

Single-axis structure motor |

Single-axis structure motor |

||

| Brand | KB/CG | KB/CG | KB/CG | KB/CG | KB/CG | ||

| Insulation class | A | A | A | A | A | ||

| Safe class | IP20 | IP20 | IP20 | IP20 | IP20 | ||

| Input | W | 55 | 55 | 64 | 64 | 64 | |

| Output | W | 25 | 25 | 30 | 30 | 30 | |

| Rated current | A | 0.25 | 0.25 | 0.29 | 0.29 | 0.29 | |

| Capacitor | uF | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Speed (Hi/Med/Lo) | rpm | 900/650 | 900/650 | 1050/850 | 1050/950 | 1050/950 | |

| Indoor Fan Wheel | Material | Aluminum Alloy | Aluminum Alloy | Aluminum Alloy | Aluminum Alloy | Aluminum Alloy | |

| Type | Cross-flow fan blade |

Cross-flow fan blade |

Cross-flow fan blade |

Cross-flow fan blade |

Cross-flow fan blade |

||

| Diameter | mm | 120mm | 120mm | 120mm | 120mm | 120mm | |

| Inch | 4.724″ | 4.724″ | 4.724″ | 4.724″ | 4.724″ | ||

| Height | mm | 706mm | 706mm | 706mm | 706mm | 706mm | |

| Inch | 27.795″ | 27.795″ | 27.795″ | 27.795″ | 27.795″ | ||

| Indoor Coil | Number of rows | 2 | 2 | 2 | 3 | 3 | |

| Tube pitch(a) x row pitch(b) | mm | 21 x 13.37 | 21 x 13.37 | 21 x 13.37 | 21 x 13.37 | 21 x 13.37 | |

| Fin spacing | mm | 1.4 | 1.4 | 1.4 | 1.6 | 1.6 | |

| Fin type (code) | Window fin | Window fin | Window fin | Window fin | Window fin | ||

| Tube outside dia. and type | mm | φ7×0.24+0.18×C | φ7×0.24+0.18×C | φ7×0.24+0.18×C | φ7×0.24+0.18×C | φ7×0.24+0.18×C | |

| Screwed pipe | Screwed pipe | Screwed pipe | Screwed pipe | Screwed pipe | |||

| Coil length x height | mm | 704 x 252 | 704 x 252 | 704 x 252 | 722 x 252 | 722 x 252 | |

| Number of circuits | 2 | 2 | 2 | 2 | 2 | ||

| Indoor Air Flow (Hi/Lo) | m3/h | 720/620 M3/h | 720/620 M3/h | 720/620 M3/h | 800/700 M3/h | 800/700 M3/h | |

| CFM | 424/365 CFM | 424/365 CFM | 424/365 CFM | 471/412 CFM | 471/412 CFM | ||

| Indoor External Static Pressure (Hi) |

Pa | 0 | 0 | 0 | 0 | 0 | |

| Indoor Sound Level (Sound Pressure Level) |

dB(A) | 49/41 | 49/40 | 49/41 | 52/49 | 52/49 | |

| Outdoor Fan Motor | Model | YDK-55-4P2-4 | YDK-55-4P2-4 | YDK-55-4P2-4 | YDK-55-4P2-4 | YDK-55-4P2-4 | |

| Type | Uniaxial iron shell | Uniaxial iron shell | Uniaxial iron shell | Uniaxial iron shell | Uniaxial iron shell | ||

| Brand | GI | GI | GI | GI | GI | ||

| Insulation class | A | A | A | A | A | ||

| Safe class | IPX4 | IPX4 | IPX4 | IPX4 | IPX4 | ||

| Input | W | 104 | 104 | 104 | 104 | 104 | |

| Output | W | 55 | 55 | 55 | 55 | 55 | |

| Rated current | A | 0.46 | 0.46 | 0.46 | 0.46 | 0.46 | |

| Capacitor | uF | 3 | 3 | 3 | 3 | 3 | |

| Speed | r/min | 1600 | 1600 | 1600 | 1600 | 1600 | |

| Outdoor Fan | Material | ABS+G15 | ABS+G15 | ABS+G15 | ABS+G15 | ABS+G15 | |

| Type | Axial-flow | Axial-flow | Axial-flow | Axial-flow | Axial-flow | ||

| Diameter | mm | 348 | 348 | 348 | 348 | 348 | |

| Height | mm | 104 | 104 | 104 | 104 | 104 | |

| Outdoor Coil | Number of rows | 2 | 2 | 2 | 3 | 3 | |

| Tube pitch(a) x row pitch(b) | mm | 14.5 x 12.56 | 14.5 x 12.56 | 14.5 x 12.56 | 21 x 13.37 | 21 x 13.37 | |

| Fin spacing | mm | 1.3 | 1.3 | 1.3 | 1.5 | 1.5 | |

| Fin type (code) | Hydrophilic Window fin |

Hydrophilic Window fin |

Hydrophilic Window fin |

Hydrophilic Window fin |

Hydrophilic Window fin |

||

| Tube outside coil | Dia.-mm | φ5 | φ5 | φ5 | φ7 | φ7 | |

| Type | φ4.9×0.2+0.15×C | φ4.9×0.2+0.15×C | φ4.9×0.2+0.15×C | φ7×0.24+0.18×C | φ7×0.24+0.18×C | ||

| Coil length x height | mm | 676 x 348 | 676 x 348 | 676 x 348 | 676 x 336 | 676 x 336 | |

| Number of circuits | 4 | 2 | 2 | 4 | 4 | ||

| Outdoor air flow | m3/h | 1200 | 1200 | 1200 | 1200 | 1200 | |

| CFM | 706.8 | 706.8 | 706.8 | 706.8 | 706.8 | ||

| Outdoor sound level (sound pressure level) |

dB(A) | 66 | 66 | 66 | 66 | 66 | |

| Unit | Dimension (W x H x D) |

mm | 1066 x 408 x 535 mm | 1066 x 408 x 535 mm | 1066 x 408 x 535 mm | 1066 x 408 x 535 mm | 1066 x 408 x 535 mm |

| Inch | 41.97×16.06×21.06 in. | 41.97×16.06×21.06 in. | 41.97×16.06×21.06 in. | 41.97×16.06×21.06 in. | 41.97×16.06×21.06 in. | ||

| Packing (W x H x D) |

mm | 1150 x 480 x 630 mm | 1150 x 480 x 630 mm | 1150 x 480 x 630 mm | 1150 x 480 x 630 mm | 1150 x 480 x 630 mm | |

| Inch | 45.28 x 18.9 x 24.8 in. | 45.28 x 18.9 x 24.8 in. | 45.28 x 18.9 x 24.8 in. | 45.28 x 18.9 x 24.8 in. | 45.28 x 18.9 x 24.8 in. | ||

| Net/Gross weight | Kg | 42.5 / 47.5 Kg | 43 / 48 Kg | 46 / 51 Kg | 49.5 / 54.5 Kg | 49.5 / 54.5 Kg | |

| Lbs. | 93.6 / 104.6 LBs | 94.7 / 105.7 LBs | 102.4 / 113.4 LBs | 109.0 / 120.0 LBs | 109.0 / 120.0 LBs | ||

| Charged refrigerant type | g | 570g | 600g | 750g | 970g | 970g | |

| Oz. | 20.11OZs | 21.16OZs | 26.46OZs | 34.22OZs | 34.22OZs | ||

| Metering device | Capillary | Capillary | Capillary | Capillary | Capillary | ||

| Design pressure | MPa | 3.1/1.6 MPa | 3.1/1.6 MPa | 3.1/1.6 MPa | 3.1/1.6 MPa | 3.1/1.6 MPa | |

| PSIG | 450/232 PSIG | 450/232 PSIG | 450/232 PSIG | 450/232 PSIG | 450/232 PSIG | ||

| Power Wires | Wire Size | mm2 | 3.3081 | 3.3081 | 3.3081 | 5.2615 | 5.2615 |

| LCDI Cord Plug | Built-in | LCDI-20A | LCDI-20A | LCDI-20A | LCDI-20A | LCDI-30A | |

| Controller | Standard: Touch Pad Optional: Remote Remote Energy Management Ready |

Standard: Touch Pad Optional: Remote Remote Energy Management Ready |

Standard: Touch Pad Optional: Remote Remote Energy Management Ready |

Standard: Touch Pad Optional: Remote Remote Energy Management Ready |

Standard: Touch Pad Optional: Remote Remote Energy Management Ready |

||

| Indoor controllable temperature ranges |

°C | 16-32 °C | 16-32 °C | 16-32 °C | 16-32 °C | 16-32 °C | |

| °F | 61-90 °F | 61-90 °F | 61-90 °F | 61-90 °F | 61-90 °F | ||

| Outdoor ambient temperature ranges |

°C | Back-up Elec. Heater ≤ -8.3°C ≤ HP 5°C ≤ AC ≤ 46.1°C |

Back-up Elec. Heater ≤ -8.3°C ≤ HP 5°C ≤ AC ≤ 46.1°C |

Back-up Elec. Heater ≤ -8.3°C ≤ HP 5°C ≤ AC ≤ 46.1°C |

Back-up Elec. Heater ≤ -8.3°C ≤ HP 5°C ≤ AC ≤ 46.1°C |

Back-up Elec. Heater ≤ -8.3°C ≤ HP 5°C ≤ AC ≤ 46.1°C |

|

| °F | Back-up Elec. Heater ≤ 17°F ≤ HP 41°F ≤ AC ≤ 115°F |

Back-up Elec. Heater ≤ 17°F ≤HP 41°F ≤AC≤ 115°F |

Back-up Elec. Heater ≤ 17°F ≤HP 41°F ≤AC≤ 115°F |

Back-up Elec. Heater ≤ 17°F ≤HP 41°F ≤AC≤ 115°F |

Back-up Elec. Heater ≤ 17°F ≤HP 41°F ≤AC≤ 115°F |

||